Ground Improvement

Continually rising real estate prices mean that even ground with less than adequate load-bearing capacity is becoming ever more attractive to developers. Ground improvement can be achieved by the highly productive methods of vibro-compaction-, vibro-displacement densification, vibro-cast-in-place- or soil stabilization columns. Selection of the most suitable method depends primarily on the ground at the site and on the loads to be carried.

Types of Construction Method

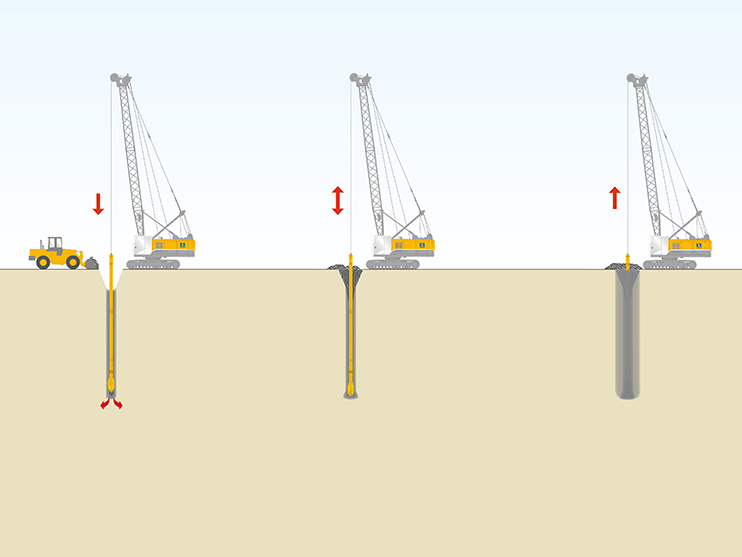

Granular or weakly cohesive sediments such as gravel and sand often have very uneven layer densities in their natural state. With vibro-compaction densification (VCD) this can be increased to around 80 %. In the process, the soil is "floated" by a water or air flush, the vibrator sinks and a settlement depression is formed at ground level. This is filled with added material. By extracting the vibrator in stages, a compacted zone 2 to 4 m in diameter is created.

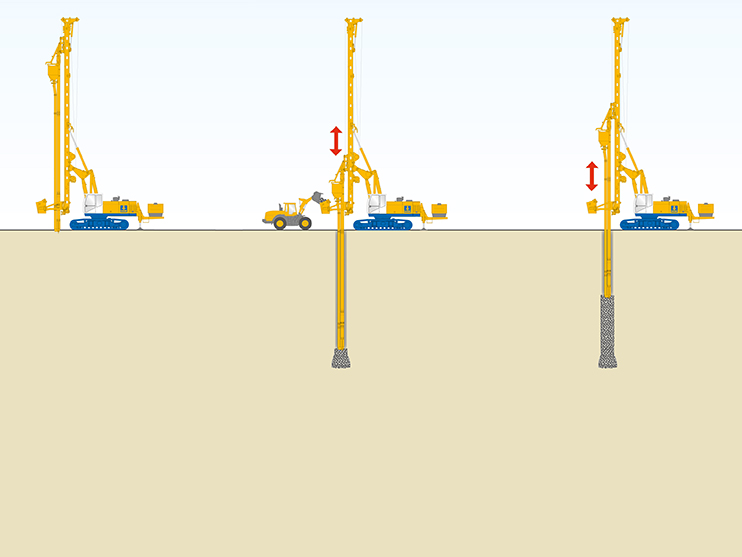

In cohesive soils it is not possible to rearrange the grains. In the vibro-displacement densification (VDD), the added material is transported directly to the vibrator tip, compacted by multiple displacement stages and pressed into the surrounding soil. This creates a crushed rock or gravel column which improves the surrounding cohesive soil due to the greater rigidity of the installed added material. Selection of the most suitable method depends primarily on the ground at the site and on the loads to be carried.

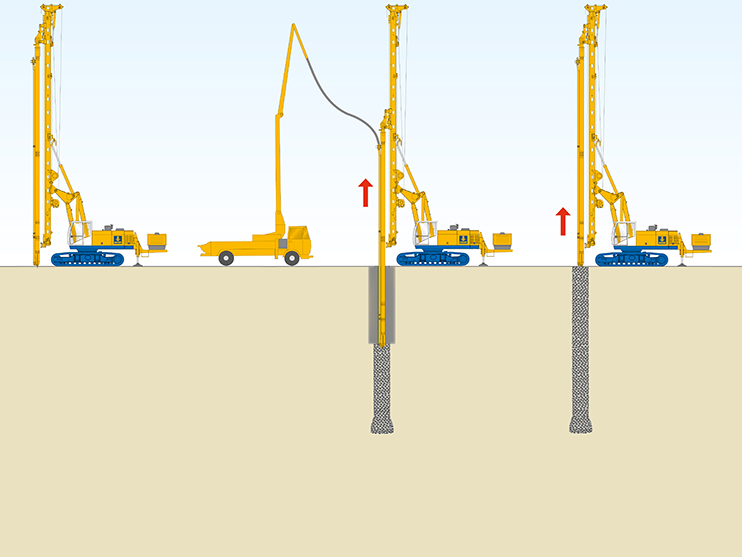

The vibro-cast-in-place columns (VCIPC) method is efficient and cost-effective in primarily cohesive, and also organic ground with very low loadbearing capacity. Thanks to the use of high-grade pumped concrete, the VCIPC have a high internal strength, regardless of the surrounding ground. VCIPC are classified according to DIN 1054 as unreinforced piles for the transmission of structural loads into deeper ground.

Soil stabilization columns are slim load-bearing elements with a minimum diameter of 15 or 180 mm. A lance is vibrated into the load-bearing horizon or to the pre-determined depth and extracted again. While this is happening, mortar is pumped into the soil under pressure. The soil stabilization columns combine load discharge transfer via skin friction and endbearing with the effect of additional ground improvement by the full displacement method.

The Mixed-in-Place method is particularly ideal in non-cohesive soils for producing cut-off walls as a soil improvement, groundwater barrier, or to encapsulate inherited pollution, for repairs to dikes and dams, or as structurally effective retaining walls for topo-graphical changes, excavation pits, as well as soil mechanical measure against liquefaction. In the Mixed-in-Place method, the existing soil is broken and mixed horizontally and vertically with a double auger, transferred and the pore spaces are filled with a binding agent slurry. The individual insertions can be used as individual elements or combined to walls using the pilgering step process. The auger dimensions ultimately determine the insertion size. Reinforcement can be inserted into the fresh Mixed-in-Place panel for structural strengthening.